Shop

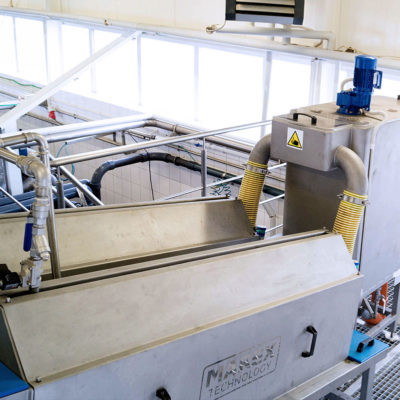

Dynamic Flocculator

The dynamic flocculator is applied to the precipitate, which is difficult to dehydration and where static mixers do not give the desired effect. Simultaneous intensive mixing and prolonged retention time lead to the formation of the fashes to be dehydrated. The flocculator is a sealed structure made of stainless steel grade.

Moduły membranowe

Moduł filtracji membranowej Alfa Laval (MFM) jest pierwszym modułem bioreaktora wykorzystującym technologię membran, który łączy najlepsze cechy sprawdzonych membran kapilarnych i membran płaskich. Cechy te znajdują się poniżej, wraz z kilkoma nowymi, uzyskanymi dzięki temu połączeniu:

- W pełni wolny przepływ między elementami membran dla nadawy.

- Wsadowe płukanie membran poprzez cyrkulację CIP lub wody płuczącej.

- Niskie zużycie energii dzięki budowie umożliwiającej łączenie pionowe modułów.

- Duża kompaktowość dzięki dużej gęstości upakowania – m2 membrany na m2 powierzchni w fabryce.

- Wytrzymałe i twarde membrany z PVDF – odporne na trudne warunki pracy.

- Grawitacyjny MBR – proste, niezawodne i oszczędne rozwiązanie.

Polylecrolimus Preparation Station

Polymers supplied in a loose or emulsion form, before being applied to the waste water treatment process, require devices preparing their solution with the appropriate parameters. Depending on the technological requirements of the property and the individual needs of the customer, Marex Technology has in its offer:

Semi-automatic stations for preparation of Polyelecrolimus

Automatic stations for preparation of Polyelecrolimus

-

Flow-through stations for preparation of Polyelecrolimus 3-cell

-

Flow-through preparation stations of Polyelecrolimus round

-

A stacking station for the preparation of Polylecrolimus

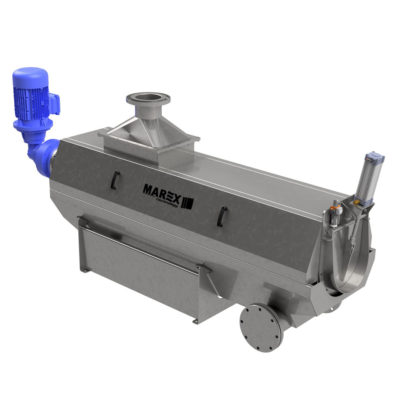

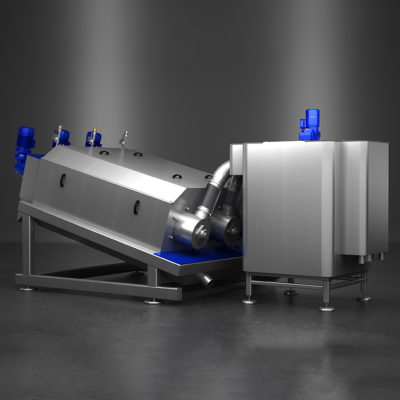

Screw Press

The screw press is used for dewatering and thicking sludge from industrial processes.

Made of 316L acid-resistant steel. Powered by a pump, gravitationally from the tank or directly from the hopper. The device is equipped with a power station. This ensures greater efficiency and a better separation rate, especially with sticky materials. The dry matter content is regulated by the pressure force of the exhaust flap of the separator.

Stair lattice

Stair grilles are designed for thorough purification – separation from industrial and municipal wastewater, large and medium-sized pollutants (waste). Then the mechanical loading of the waste into the transport device or to the garbage container is carried out.

The grille can be installed in the ducts of sewage pumping stations and sewage treatment plants in buildings intended for grat.

Винт Пресс

Винтовой пресс используется для обезвоживания и толщины шлама от промышленных процессов.

Изготовлен из 316L кислотостойкой стали. Работает на насосе, гравитационно из бака или непосредственно из бункера. Устройство оснащено электростанцией. Это обеспечивает большую эффективность и лучшую скорость разделения, особенно с липкими материалами. Содержание сухого вещества регулируется силой давления выхлопного лоскута сепаратора.

Dmuchawy walcowe

Dmuchawy walcowe wykorzystywane w biologicznej części oczyszczalni ścieków, w sekcji napowietrzania biologii tlenowej oraz także w sekcji membran do ich oczyszczania z osadów zaległych na powierzchni zewnętrznej membrany.

Dmuchawy te są kompaktowych rozmiarów co jest ważne dla inwestora nie zajmują dużo miejsca, a ich budowa zapewnia dostęp do najważniejszych elementów eksploatacyjnych od przodu urządzenia dzięki czemu można umieścić kilka dmuchaw obok siebie bezpośrednio.

Urządzenia te dobierane są dokładnie dla zapotrzebowania na powietrze doprowadzane do komory tlenowej lub do modułów membranowych. Istnieje także możliwość umiejscowienia dmuchaw poza budynkiem.

Poultry Transport Containers

As a company that corresponds to all the needs of its customers, MAREX has created easy-to-use containers. Thanks to the use of containers no damage is recorded during loading and unloading of animals, which allows to compensate for transport falls. The most significant advantage of containers is their simple unloading, with the help of a forklift or telehandler the unloading of 20 containers lasts only 30 minutes.

Chamber Press

Filter presses are used to filter different types of deposits. They are used in the food, pharmaceutical, cosmetic and chemical industries.

The use of presses in the filtration process allows for the achievement of high accuracy and efficiency. The chamber filter Press in its construction has a plate with internal connections, which are compatible with a large number of types and sizes of filter materials, including paper cartridges and textile filters. In the case of internal connections, the filter material itself acts as a sealing function and thus eliminates the problem of the selection of seals for various products.

Storage tanks for chemical reagents

The tank is made of acid-resistant steel or plastic. Its capacity depends, among other things, on the performance of the vacuum cleaner, the size of the room and the need for emptying.

Principle:

The purpose of the Poflotation sludge tank is to homogenize and accumulate the afterflotation sludge, which will be directed to the sludge Dewatering station in the downstream parts. The tank will also be able to mix the post-flotation sludge with deposits that are excessive from the biological treatment plant.Equipment:

The tank is equipped with a paddle stirrer to prevent the sludge from freezing. The agitators operate in automatic mode.Advantages:

- Easy access to mechanical parts

- Simple operation

- Manufacture from chemically resistant or acid-resistant materials

Arc Sieve

A sieve designed thanks to many years of experience in various industries. The filtered medium is given to the flow chamber at the top of the arc filter.

Principle:

After overflow of the flow chamber, the medium flows into the ARC cartridge (parabolic sieve, curved screen) made from the slotted sieve and through the gaps in the siting flows into the drain chamber at the bottom of the arc filter. The solid parts stuck through the parabolic sieve slots slip downward under the influence of gravity and the arch shape of the sieve.Equipment:

- Flow Chamber

- Parabolic slotic Sieve

- Outflow Chamber

Advantages:

- Very simple operation

- No electricity demand

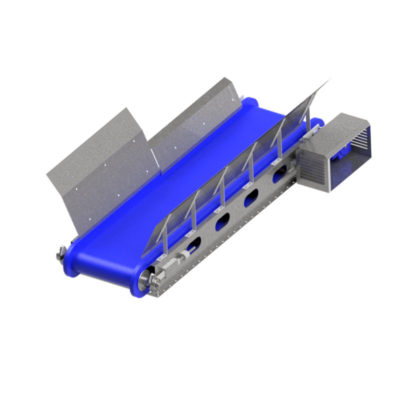

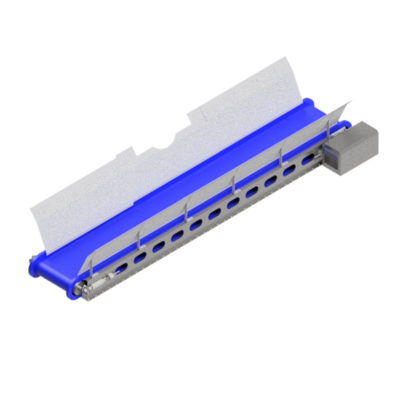

Belt Press

The principle of operation of the press is transparent and contains all the necessary steps in dewatering the sludge.

The condensed sludge in the pre-thicker is fed into the low pressure zone tape. In this zone, the precipitate is evenly distributed over the width of the tape and dehydrated under the progressively increasing pressure of the successive pressure plates alternately with the bursting comb. At the end of the low pressure zone, the precipitate enters the sphenoid zone, where it is gradually squeezed between the conveyor belt and the tape-clout of the filter cylinder.

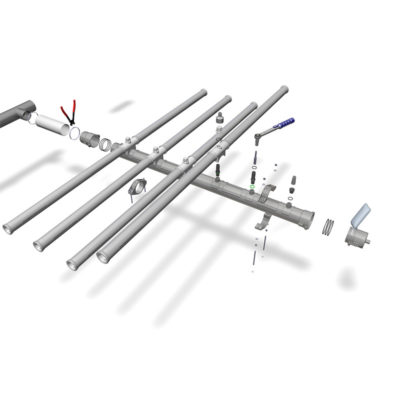

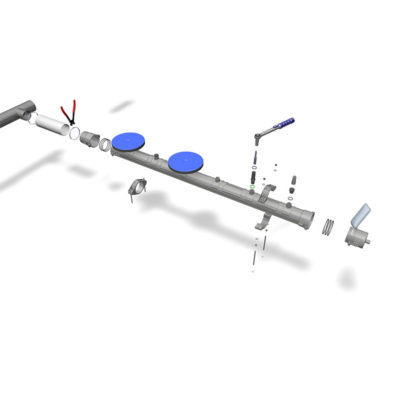

Tube Diffusers STANDARD 2

The OTT STANDARD 2 is the ideal tube diffuser for installation in existing wastewater treatment plants. Like all OTT tube diffusers, STANDARD 2 includes patented technical solutions, including an integrated air duct that provides an even distribution of airflow along the entire diffuser length and membrane mounting edge, For safe and folds-free membrane positioning.

The OTT STANDARD 2 diffusers can be quickly and easily mounted on rectangular heads with outlet openings of 30, 40 or 45 mm diameter. They are mounted in pairs using double threaded connectors available in PP-GF structural plastics, alternatively in stainless steel grade VA or brass.

The OTT STANDARD 2 diffusers can also be mounted on round heads with a diameter of 20 mm outlet holes. Secure mounting provides a saddle-shaped adaptor. These rugged adaptors ensure reliable operation at high operating temperatures and exceptional resistance to formic acid.

The OTT STANDARD 2 tube diffusers are available from stock in 500, 750 and 1000 mm effective lengths. Individual lengths, e.g. In the case of trailer-mounted machining units or MBR modules, they can be produced accurately according to your specifications.

Tubular Flocculator

Tubular Flocculator-It is used for chemical precipitation of pollutants from wastewater by means of coagulants and flocculants, correction of pH and formation of larger, easily separable agglomerates, so-called. The flokuł.

Tubular flocculators provide optimum dispersion of larger particles, which then flow to the flotators or settlers. The Flocculator design provides sufficient time for the mixing of wastewater and provides optimum conditions for the formation of large flocuents, without the need for mechanical mixing.

Equipment:

- Flow meter

- Automatic gate valve for regulating the flow of chemistry

- Dosing nipple for chemical reagents

- Appropriate sensors to control the processes

Advantages

- Construction to accelerate the flow of wastewater

- Made from materials resistant to aggressive wastewater and chemical agents

Construction:

Through pipe of appropriate length and diameter. The built-in sockets allow for the connection of chemical agents and pH probes, and the corresponding ports allow to control the process overlap after each of the measures. The Flocculator design allows to increase the flow velocity of the liquid for optimum dispersion of chemistry in its respective sections.Cylindrical sieve

The device is used for sewage treatment of solid contaminants of a size exceeding 0.5 mm. Completely made of acid-resistant materials.

Principle:

Sewage (gravity or pump) is brought into the interior of the cylindrical sieve. The Skratki is retained in the trough of the sieve and the separated liquid flows gravitationally to the outside of the device. Cleaning knives collect particles greater than 0, 5mm, which are routed to the part of the treatment plant responsible for waste management. The machine is working until the desired liquid level is obtained, followed by reversing the direction of movement of the drum and automatically attaching the spray nozzles – the cleaning process. The operation of the cylindrical separator is in automatic mode.Equipment:

- Rotary drum made of cylindrical trapezo rods with a clearance of 0.5 mm

- Drive unit

- Pressurized Central washing system

Advantages:

- Excellent pre-treatment of wastewater

- Low power consumption

- High effectiveness of sieve cleaning (in automatic mode)

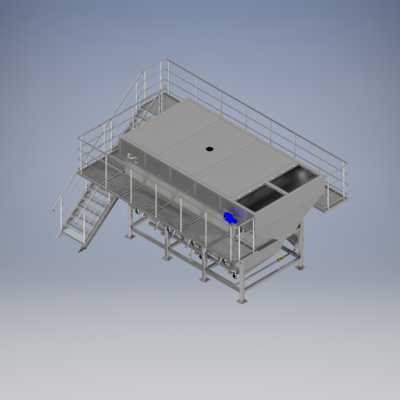

Flotator

The flotator consists of a tank in which the flotation process is carried out, on the bottom of which there are small-body diffusers, and from the foam collection system.

The precision of the Flotator basin and the method of producing bubbles determine the effectiveness of the flotation, because it is very important that the liquid in the fleet is in laminar and not turbulent flow conditions. This ensures that the lint of the substances that have formed at an earlier stage of coagulation is not disrupted. A well-constructed and constructed flotator therefore enables better technological parameters, i.e. savings on chemicals dispensed in the purification process. This modern device is also metering, allowing its integration with data transmission systems.

OTT Pipe Membranes

OTT pipe membranes are available in EPDM (FLEXNORM®) and SILICONE (flexsil®/flexsil +®) versions.

FLEXNORM® -recommended for use in municipal wastewater

- High-quality raw materials, including biologically resistant plasticiser

- Long service life of up to 80 °C.

- Possibility of various perforations

FLEXSIL® -recommended for use in harsh wastewater

- Working at compressed air temperature up to 110 °C

- Made of construction materials without plasticisers

- Fully resistant to Bioszlam, a wide range of chemicals and oils and lubricants

FLEXSIL®+

- Better non-adhesive behaviour

- Working at compressed air temperature up to 110 °C

- Made of construction materials without plasticisers

- Fully resistant to Bioszlam, a wide range of chemicals and oils and lubricants