Polymers supplied in a loose or emulsion form, before being applied to the waste water treatment process, require devices preparing their solution with the appropriate parameters. Depending on the technological requirements of the property and the individual needs of the customer, Marex Technology has in its offer:

Semi-automatic stations for preparation of Polyelecrolimus

Automatic stations for preparation of Polyelecrolimus

-

Flow-through stations for preparation of Polyelecrolimus 3-cell

-

Flow-through preparation stations of Polyelecrolimus round

-

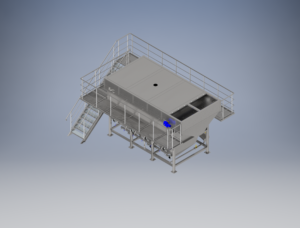

A stacking station for the preparation of Polylecrolimus

The two-storey unit is made of 316L acid-resistant steel using components from leading manufacturers. The device is used to precisely fill the chamber with water and polyester powder and to dissolve and mix the ingredients perfectly. The station is operating in automatic mode, resulting in a continuous cycle of preparation and administration of Polylecrolimus.

On the first floor a stirrer with motor is mounted, then a Polylecrolimus reservoir is mounted with a worm-shaped and conical funnel for hydration of polylecrolimus. Two solenoid valves are installed on this floor for automatic water feeding. A pressure transmitter is mounted on the lower part I of the floor for precise water filling and polyelecrolimus in the working chamber and the floor of the automatic chemistry station.

In the tank under the I-floor, a stirrer with SIEMENSA motor is fitted with an electric flap valve Ø 70 by GEORGA FISHERA, suction lance for flocculant dosing pump and CERABAR pressure transducer for minimum/maximum signalling. Capacity of automatic Stacking station: 0.5-1.5 m3/h