Shop

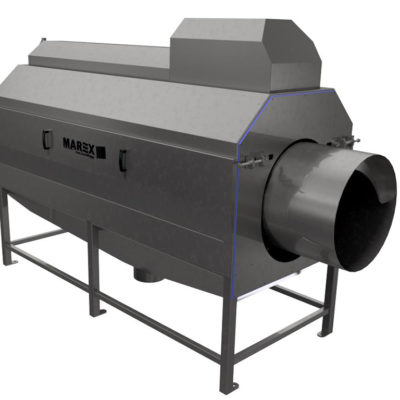

Separator with internal inflow

The main element of the machine is the cylindrical body embedded on the carrier frame. A sieve driven by a geared motor is embedded in the body. Inside, the body is made to get the best working conditions.

Principle:

The injected feed is picked up and headed upwards. During the rotation, the water flows through the sieves into the sewage trough down to the sewer trough located at the bottom of the cylindrical body. The dewatering load is routed to the outlet at the top. For better working conditions inside the machine, a water sprinkler controlled by an solenoid valve was mounted.Belt Filter

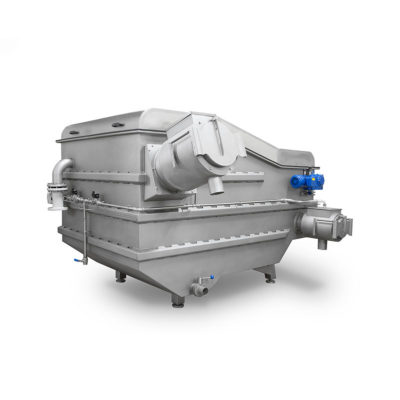

The belt filter, currently considered the world's most efficient and cheapest in operation, is a device for the removal of slurries from wastewater and simultaneous dewatering of sediment.

Principles of Operation:

The process of removing slurries consists of leaching sludge during transport on a filter net, from which the sludge is discharged into the screw thickener by compressed air. The dehydrated sludge has low humidity (often below 70) which facilitates further disposal.Equipment:

- Air blower for blow belt

- Hot water Washing System

Advantages

- Reducing the consumption of chemicals compared to Rotositami

- No servicing, except maintenance only 1-2 hours per week

Biofilter

Biofilters clean the air from gaseous, volatile and aerosol substances in waste and polluted air.

Biofilters are not filters in the technical sense of the word, these are complicated biocatalizers or bioreactors. Through the metabolism of microbial biofiltrics, toxic, ominous substances are transformed into harmless, odour-neutral chemical compounds such as carbon dioxide and water (H2O and CO2).

A material that is filled with a biofilm absorbent the substances that are ominous and toxic from the air stream delivered to the device. Microorganisms located on and in the fibres decompile the supplied practical substances in 100.

Biofilters can be used to clean the air with a mixture of solvents from production plants for example, paintshop, ominous air from sewage treatment plant, food processing plants, forage production plants, composters. The requirements and application range of Biofilters is contained in VDI Richtlinien 3477 "Biofilter".

In order to ensure effective, long-term work and proper functioning of the equipment, it is necessary to ensure appropriate physico-chemical conditions inside the appliance. Parameters such as temperature, air humidity, PH, the amount of organic compounds supplied to the device affect the effectiveness of the metabolism.